Ok, so I just ordered a set of P90s from Wolfetone for my 1986 Gibson SG Standard. (Mean/Meaner) I've been wanting a P90 guitar for as long as I can remember, I've been playing 41 years and have owned mostly Gibsons with humbuckers. This particular SG I found in a local music shop back in the early 1990s and it was so cheap I felt compelled to buy it even though I didn't really need another Gibson with buckers. It started out as a black guitar and looked really nice when I first bought it. After a while, the finish began to flake off, not just a little but in large shards. So being borderline obsessive/compulsive, I began helping the process along, mainly because I couldn't have this guitar exfoliating everywhere it goes. But there was a bigger problem than this black snake of a guitar shedding it's skin every where, the tone of this guitar was below mediocre. I understood why I got it so cheap, it needed a better set of pickups. So I set about finding a nice upgrade to the stock pickups an settled on a set of used Gibson 57 classics I found in a box on the counter of Dave's Guitars up in LaCrosse, Wi. Back then, Dave would sell pickups and parts that were taken out of customers guitars when they were brought in for mods. I got a killer price for them and totally expected these pickups to radically transform the tone my skin shedding SG. They only marginally improved the sound, and to say the least, I was pretty bummed out about the whole deal so I put the guitar away in a closet and didn't really think about for a couple decades.

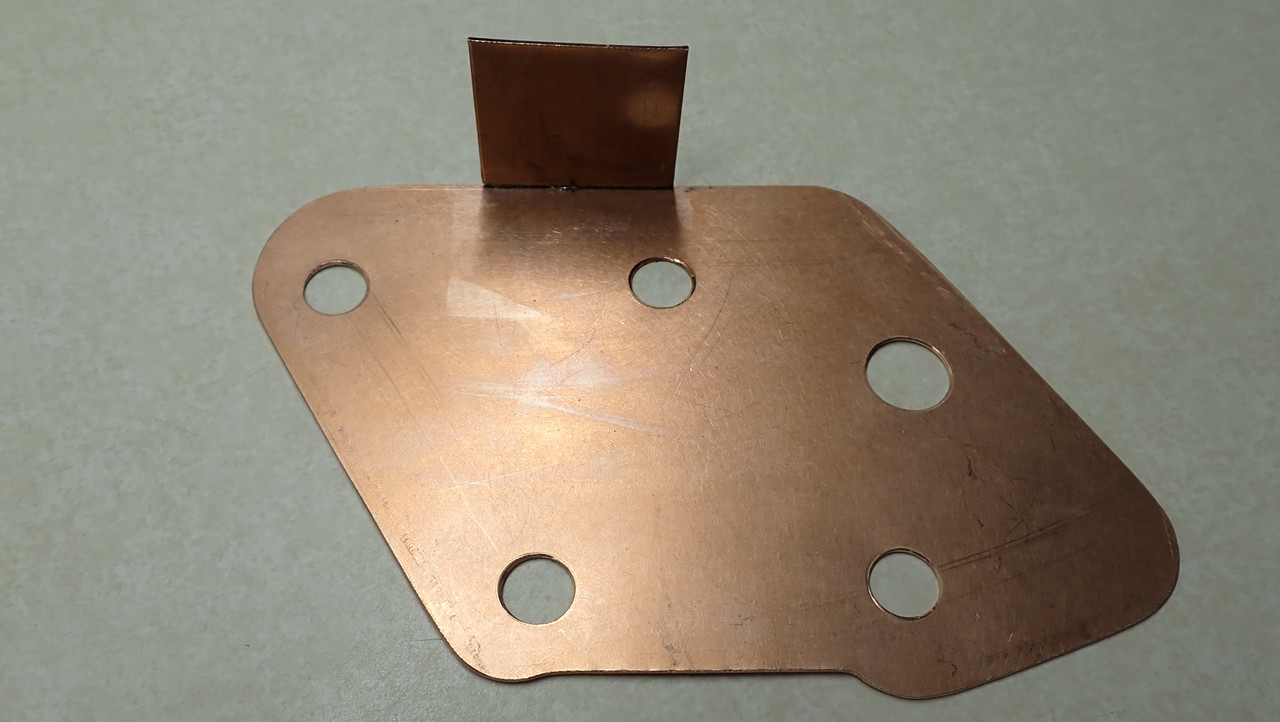

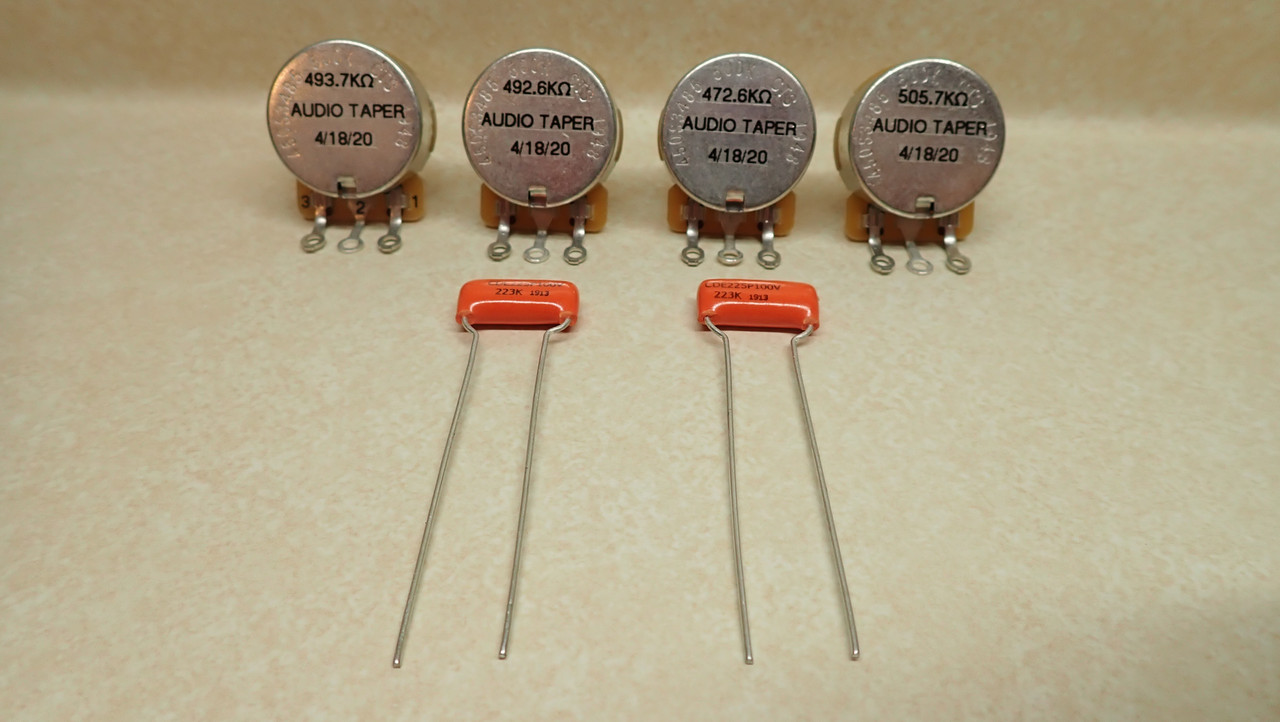

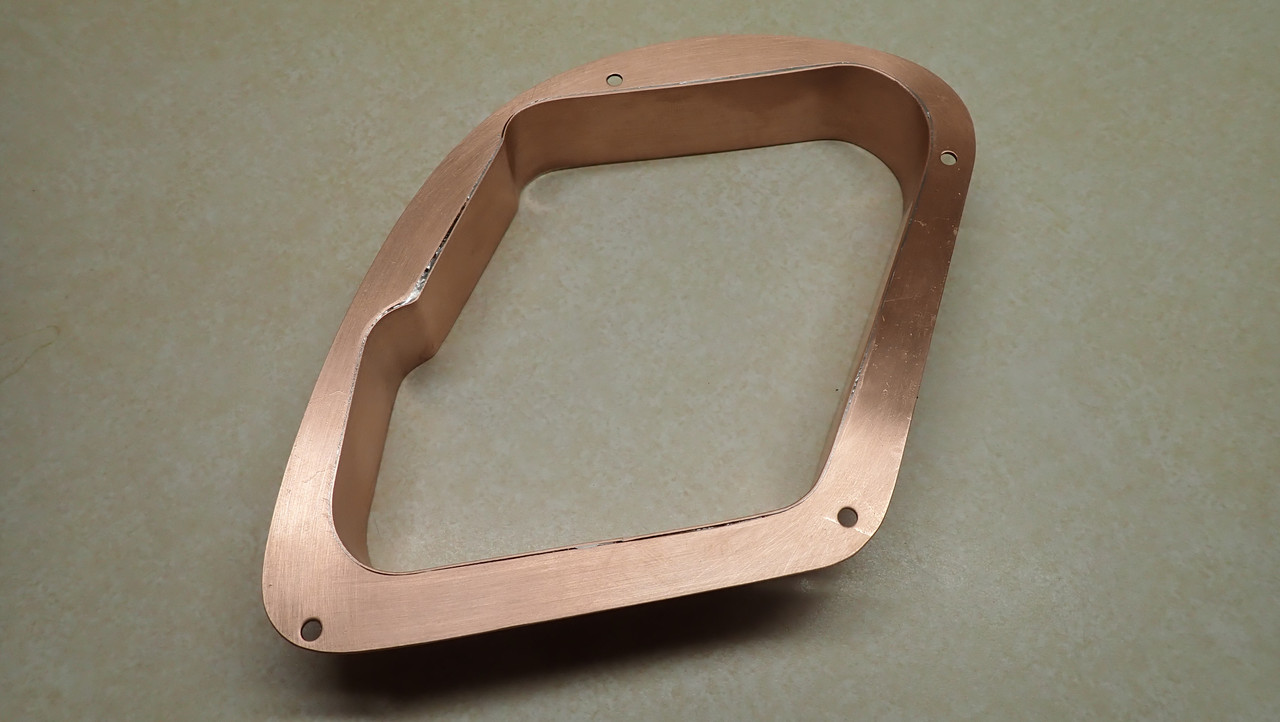

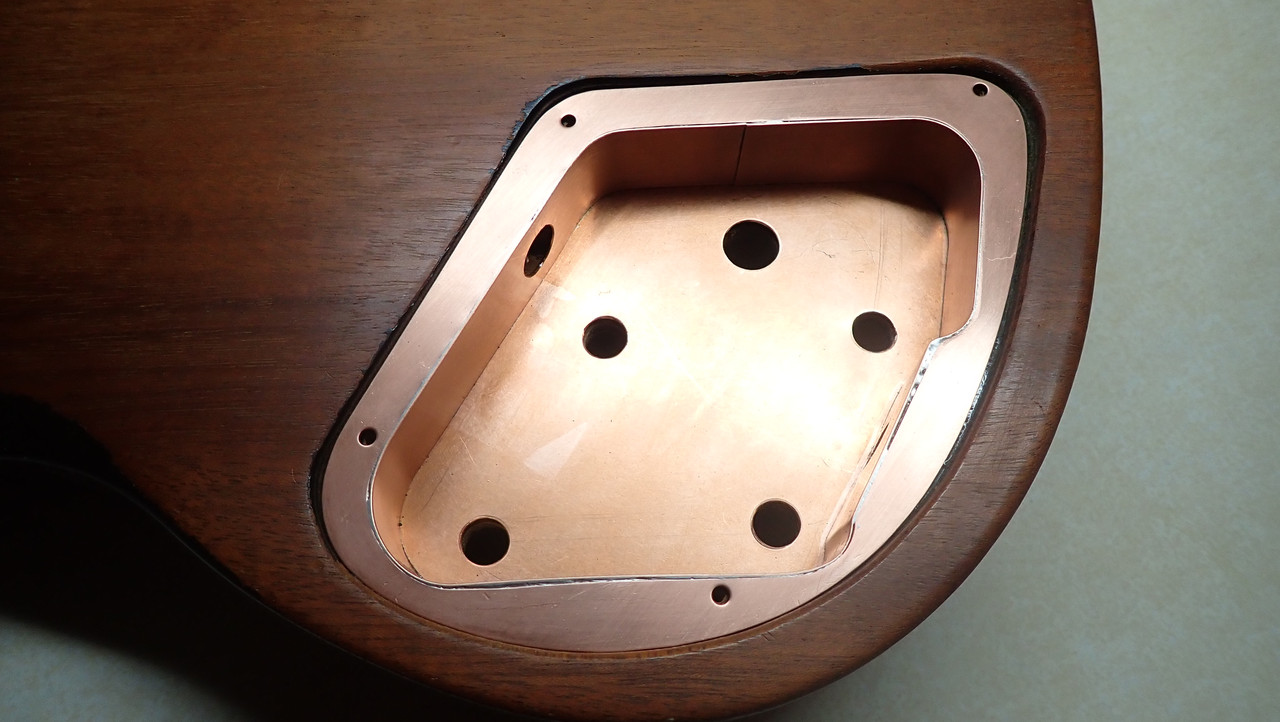

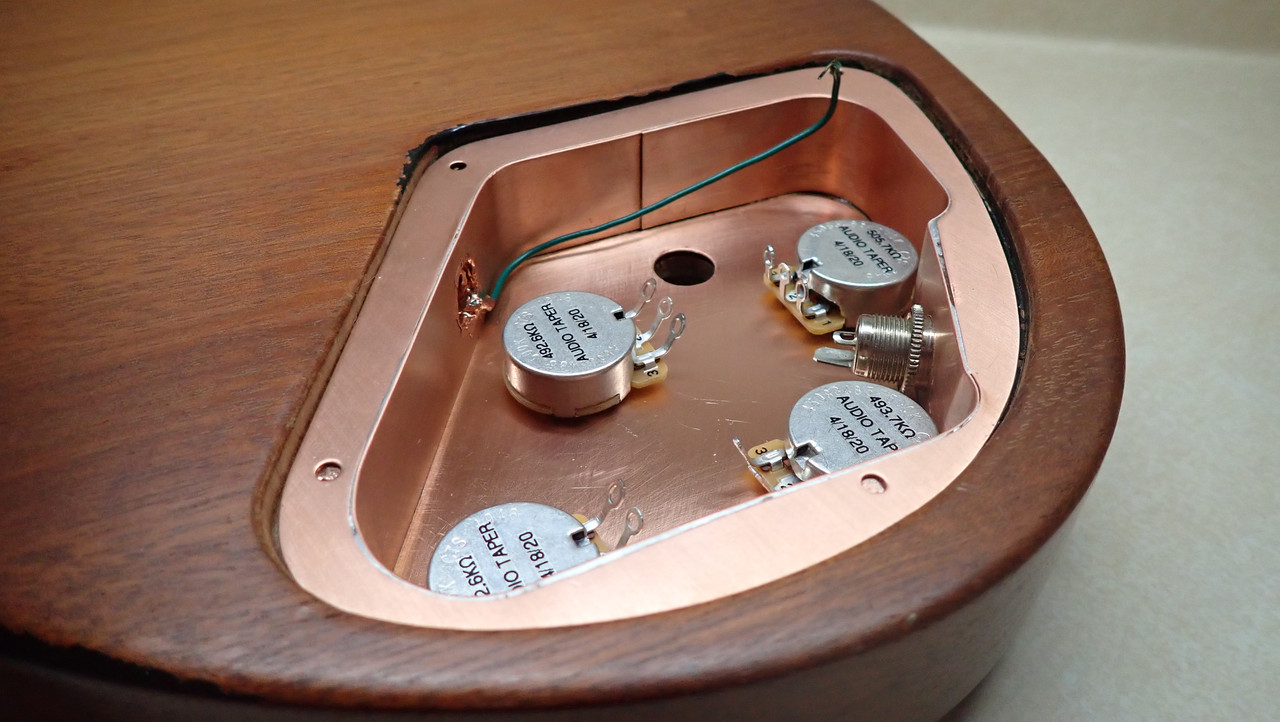

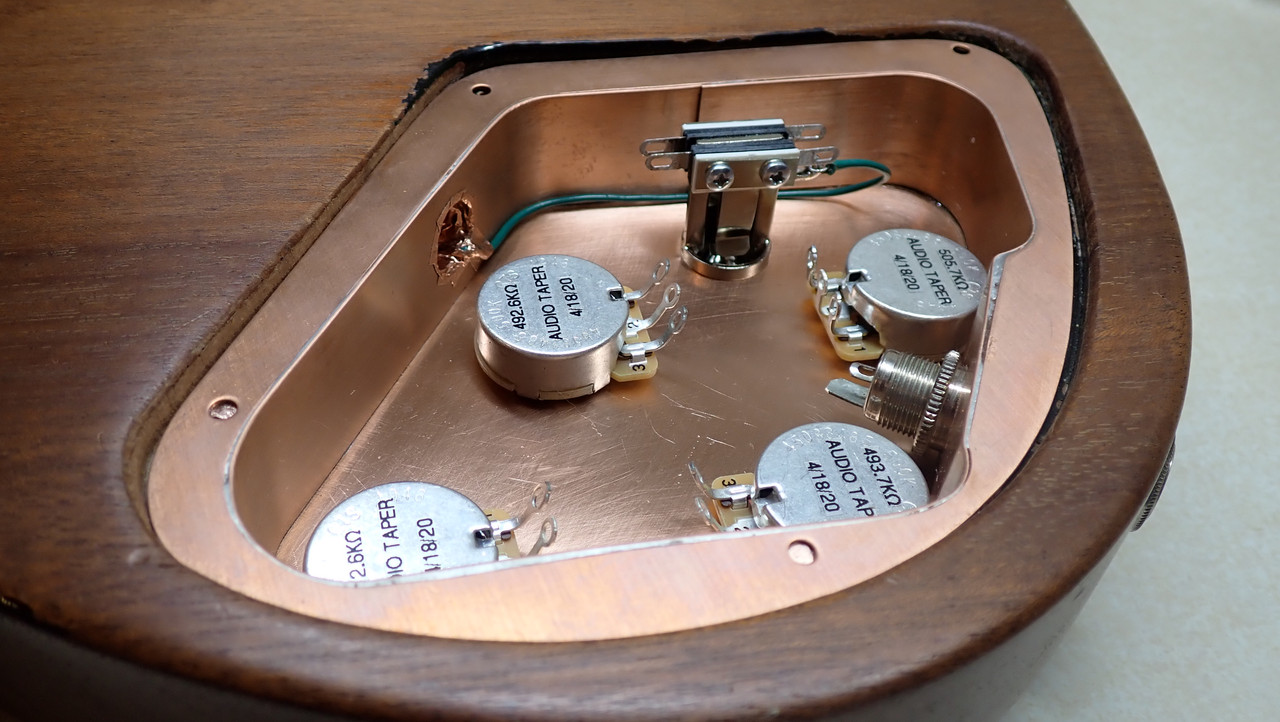

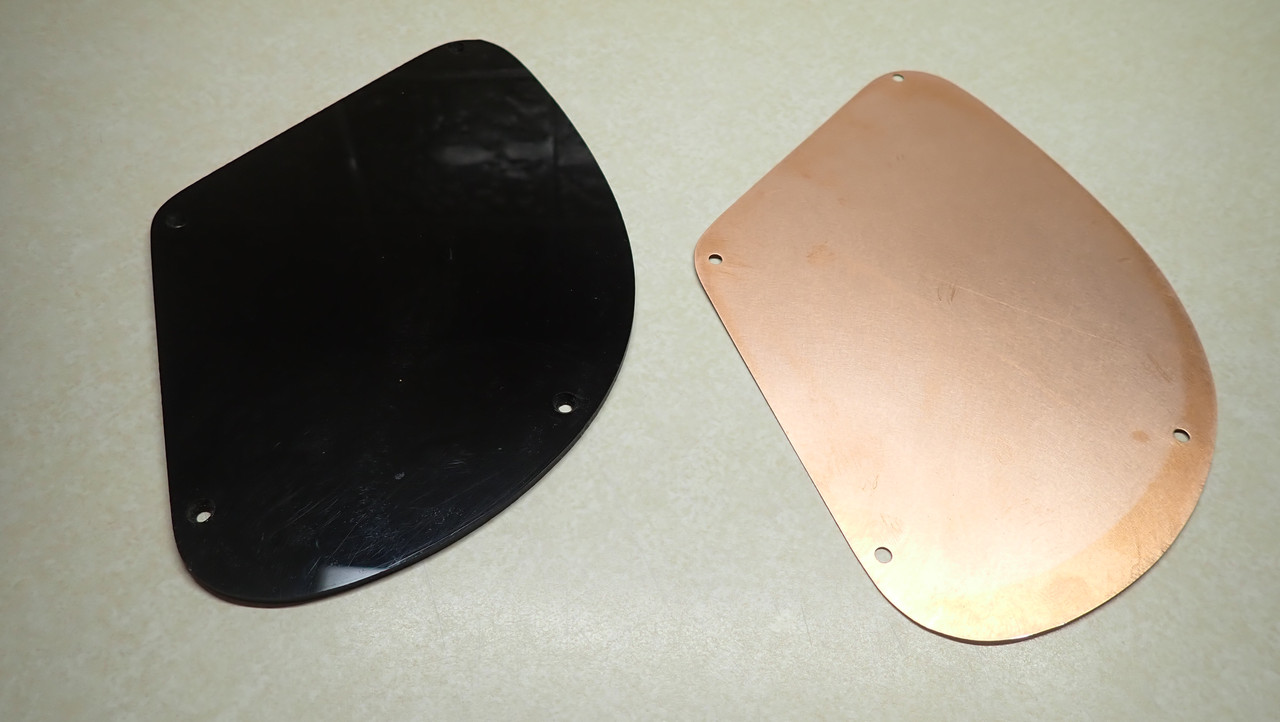

So lately I've been thinking more and more about what it would take to put P90s in this forsaken and nearly naked SG that I've had forever and have barely played. So I ordered a "batwing pickguard", new CTS 500k pots (audio taper), New Wolfetone P90s (Mean and Meaner), and supplies to "faraday cage" the control cavity and the pickup pockets. I've already started the project but haven't taken any pics yet. I'll try to document the project as best I can, but for now, here's a pic the SG before any work was done.

So lately I've been thinking more and more about what it would take to put P90s in this forsaken and nearly naked SG that I've had forever and have barely played. So I ordered a "batwing pickguard", new CTS 500k pots (audio taper), New Wolfetone P90s (Mean and Meaner), and supplies to "faraday cage" the control cavity and the pickup pockets. I've already started the project but haven't taken any pics yet. I'll try to document the project as best I can, but for now, here's a pic the SG before any work was done.

Last edited: